O ring

- Brand:R.S.L.

- Model:O-ring

- Minimum:1000pieces

- Material:EPDM、NBR、NR、SBR、VITON、Silicone Rubber

- Payment:T/T or L/C

O-rings are the most common mechanical design for sealing because of their low cost, simple manufacturing, reliable operation and simple installation requirements. O-rings withstand dozens of pascal (thousand pounds) pressure. O-rings can be used in static applications and can also be used in dynamic applications where relative movement between components, such as rotating the shaft of the pump and the hydraulic cylinder piston.

O ring description

How to describe an O-ring?

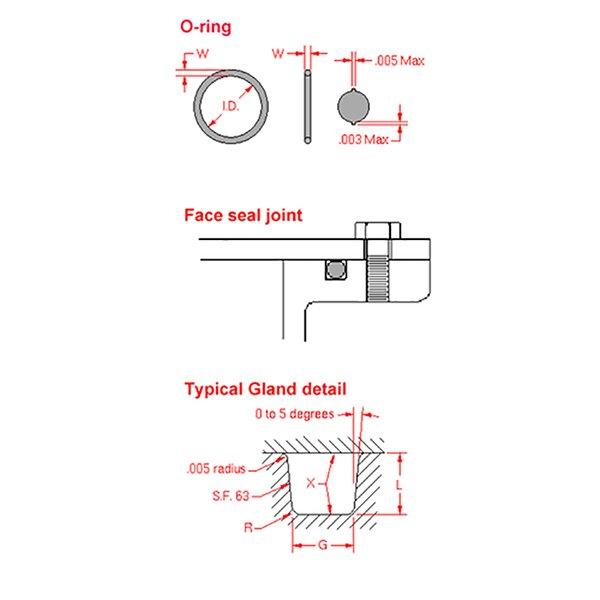

Custom Orings and Metric Orings are typically described by their Internal Diameter (ID), Radial Cross Section (CS), Rubber Material from which they are constructed plus the material Hardness on a Shore A scale .

We offer the following six (6) standard rubber materials in a range of durometer (Shore A) hardnesses to satisfy practically any service condition:

Viton® / FKM: Fluorocarbon (Viton®) exhibits exceptional resistance to chemicals, oils, temperature extremes (-13°F to +446°F), low compression set, low gas permeability and excellent aging characteristics. Applications include: aircraft engines, automotive fuel handling systems, and chemical processing industries. FKM is also suitable for high vacuum applications. It is not recommended for exposure to ketones, alkalis, and Skydrol® fluids. Custom compounds are available with improved chemical and low temperature resistance. Read More

Nitrile / NBR: Nitrile (Buna-N) is the most widely used elastomer due to its excellent resistance to petroleum products, operating temperature range (-40°F to +257°F) and one of the best performance-to-cost values. It's an ideal material for aerospace, automotive, propane and natural gas applications. Special Hydrogenated Nitrile (HNBR) compounds can improve resistance to direct ozone, sunlight, and weather exposure while increasing temperature range to +300°F. Read More

Ethylene-Propylene / EPDM: EPDM has outstanding resistance to heat, water and steam, alkali, mild acidic and oxygenated solvents, ozone, and sunlight (-40ºF to +275ºF); but it is not recommended for gasoline, petroleum oil and grease, and hydrocarbon environments. This popular rubber compound is usually the first choice for low torque drive belt applications. Read More

Fluorosilicone / FVMQ: Fluorosilicone (-75º to +400ºF) combines the good high and low temperature stability of silicones with the fuel, oil, and solvent resistance of fluorocarbons. FVMQ is unparalleled for aerospace fuel systems, auto fuel emission control systems and to meet or exceed government, military, aerospace, automotive, industrial and commercial specifications. However, due to relatively low tear strength, high friction and limited abrasion resistance of these materials, they are generally not used in dynamic applications. They are also not recommended for exposure to brake fluids, hydrazine, or ketones. Read More

Silicone / VMQ: In the Silicone family, you will find compounds which are superior as static seals in extreme temperature conditions. Standard compounds handle operating temperatures -85º to +400ºF. Silicone compounds are popular in food and medical applications because they are very clean and do not impart odor or taste. Special Phenyl silicones can be used down to -148°F. Read More

Neoprene® / CR: Neoprene (-40º to +250ºF) is reasonably priced and features good resistance to petroleum oils, ozone, sunlight and oxygen aging, relatively low compression set, good resilience and outstanding physical toughness. It is the preferred sealing material for the refrigeration industry because of its resistance to ammonia and Freon®. Read More

Let us know if you require materials to meet the following standards; UL, WRAS, ASTM, NSF-61. We have many special compounds that can meet the specification you are looking for.

O-rings are the most commonly used sealing products. They are very effective as well as being relatively inexpensive and reliable.

O-rings are designed to offer sealing in both static and dynamic applications.

A wide range of elastomers are available including Nitrile (NBR), Hydrogenated Nitrile (HNBR), Silicone (VMQ), Polyurethane (PU), Perfluoroelastomer (FFKM), Viton®/ FKM and PTFE. As well as standard grades,many derivatives are also available.

|

Property |

Buna-N |

Viton® |

Silicone |

PTFE |

Kalrez® |

|

Part No. Prefix |

B- |

V- |

S- |

T- |

K- |

|

Tear Resistance |

Good |

Good |

Poor |

Excellent |

Good |

|

Abrasive Resistance |

Good |

Good |

Poor |

Excellent |

Good |

|

Ozone Resistance |

Poor |

Excellent |

Excellent |

Good |

Excellent |

|

Weather Resistance |

Fair |

Excellent |

Excellent |

Good |

Excellent |

|

Heat Resistance |

Fair |

Excellent |

Excellent |

Good |

Excellent |

|

Chemical Resistance |

Fair |

Excellent |

Good |

Excellent |

Excellent |

|

Oil Resistance |

Poor |

Excellent |

Poor |

Good |

Excellent |

|

Acid Resistance |

Fair |

Excellent |

Good |

Excellent |

Excellent |

|

Alkali Resistance |

Good |

Good |

Fair |

Excellent |

Excellent |

|

Steam Resistance |

Fair |

Fair |

Poor |

Good |

Excellent |

|

Minimum Usable Temp |

-65 deg F |

-65 deg F |

-120 deg F |

-110 deg F |

-35 deg F |

|

Maximum Usable Temp |

300 deg F |

500 deg F |

450 deg F |

500 deg F |

550 deg F |

|

Color |

Black |

Black |

Red |

White |

Black |

|

Impermeability |

Fair |

Good |

Poor |

Excellent |

Good |

|

Tensile Strength |

Good |

Good |

Poor |

Excellent |

Good |

|

Type |

[ M ]Material |

[ H ] Hardness (JIS Hs) |

Color |

Operating Temperature Range |

Applications |

Feature |

|

NSA |

Nitrile Rubber |

70±5 |

Black |

-30~100°C |

Mineral Oil Resistant |

Most representative material with superior oil / abrasion resistance and heat stability. |

|

NSB |

Nitrile Rubber |

90±5 |

Black |

-25~100°C |

||

|

NSSW |

Silicon Rubber |

50±5 |

Milky White |

-50~200°C |

Heat Resistant |

Having excellent high and low temperature resistances, this material has the widest range of operating temperatures among synthetic rubbers.It is suitable for food-related applications. |

|

NSS |

Silicon Rubber |

70±5 |

Dark Blue[ ! ] |

-50~200°C |

Heat Resistant |

|

|

NSF |

Fluoro Rubber |

70±5 |

Black |

-15~200°C |

Best in oil / chemical resistance and heat stability as synthetic rubber. Suitable for a wide range of applications. |

|

|

NSFH |

Fluoro Rubber |

90±5 |

Black |

-15~200°C |

Heat Resistant |